TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® N-BK7 Wedged Windows are available in standard metric sizes with a 30 arcminute wedge. The wedge of these windows eliminate Etalon effects by preventing back surface reflections from traveling along the same optical path as the transmitted beam. In laser cavities, wedged windows help prevent laser instability, mode-hopping, and power spikes caused by these unwanted reflections. TECHSPEC N-BK7 Wedged Windows are often used as a cost-effective alternative to Fused Silica Wedged Windows in applications that do not require UV transmission or where high thermal stability is not required such as with low power visible or NIR lasers. Wedged windows can also be used as beam samplers or beam pick-off optics to monitor laser beam properties such as beam power over time.

| N-BK7 | |

|

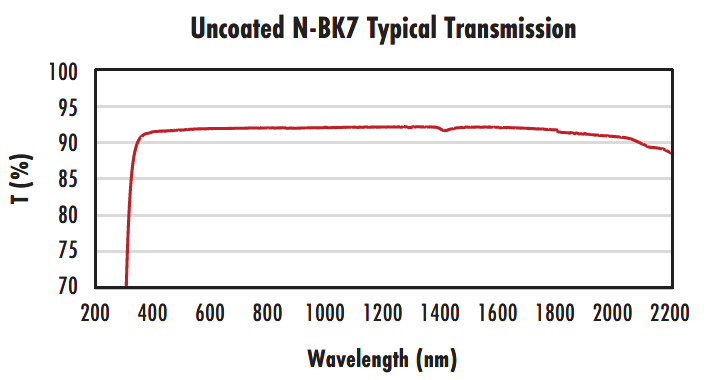

Typical transmission of a 3mm thick, uncoated N-BK7 window across the UV - NIR spectra. |

|

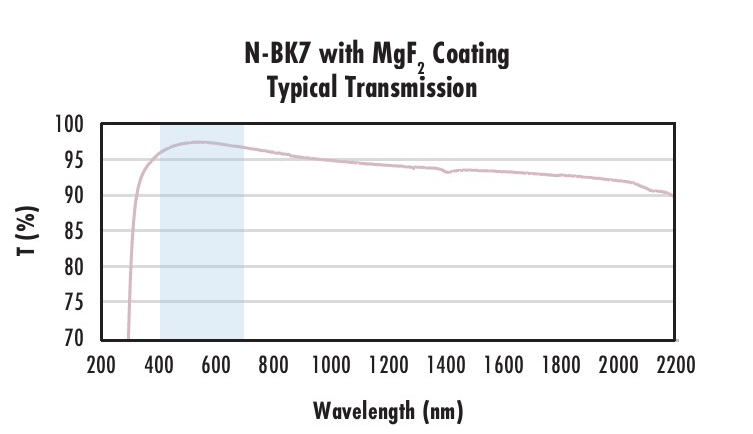

Typical transmission of a 3mm thick N-BK7 window with MgF2 (400-700nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Ravg ≤ 1.75% @ 400 - 700nm (N-BK7) Data outside this range is not guaranteed and is for reference only. |

|

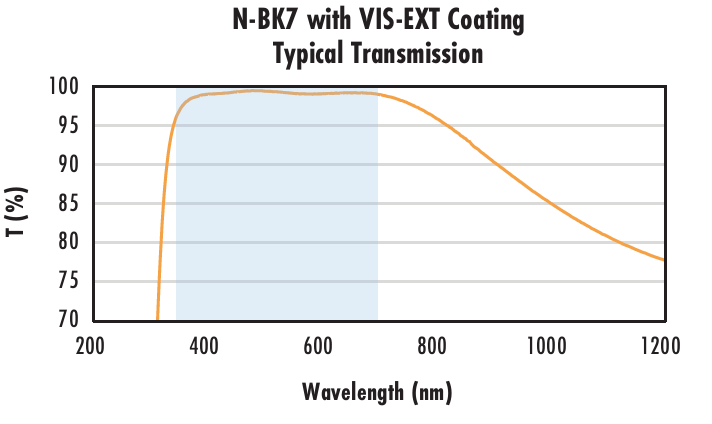

Typical transmission of a 3mm thick N-BK7 window with VIS-EXT (350-700nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Ravg ≤ 0.5% @ 350 - 700nm Data outside this range is not guaranteed and is for reference only. |

|

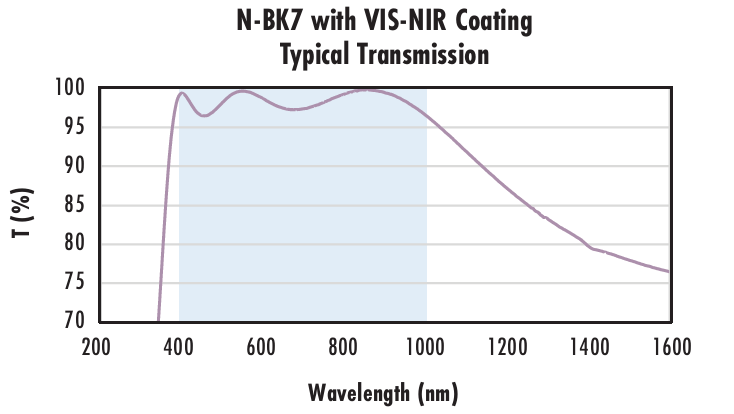

Typical transmission of a 3mm thick N-BK7 window with VIS-NIR (400-1000nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Rabs ≤ 0.25% @ 880nm Data outside this range is not guaranteed and is for reference only. |

|

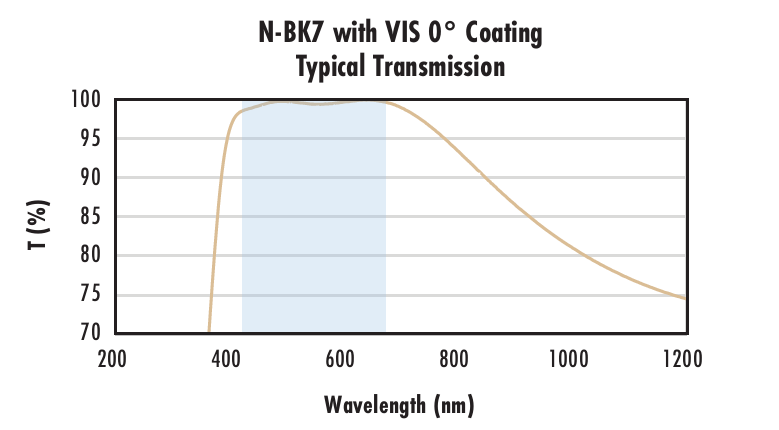

Typical transmission of a 3mm thick N-BK7 window with VIS 0° (425-675nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Ravg ≤ 0.4% @ 425 - 675nm Data outside this range is not guaranteed and is for reference only. |

|

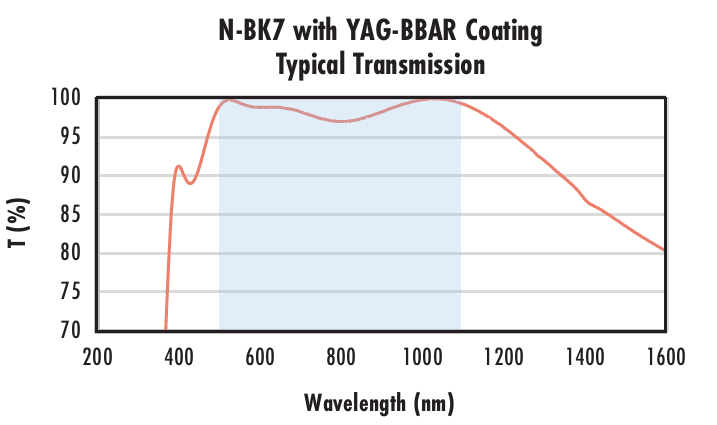

Typical transmission of a 3mm thick N-BK7 window with YAG-BBAR (500-1100nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Rabs ≤ 0.25% @ 532nm Data outside this range is not guaranteed and is for reference only. |

|

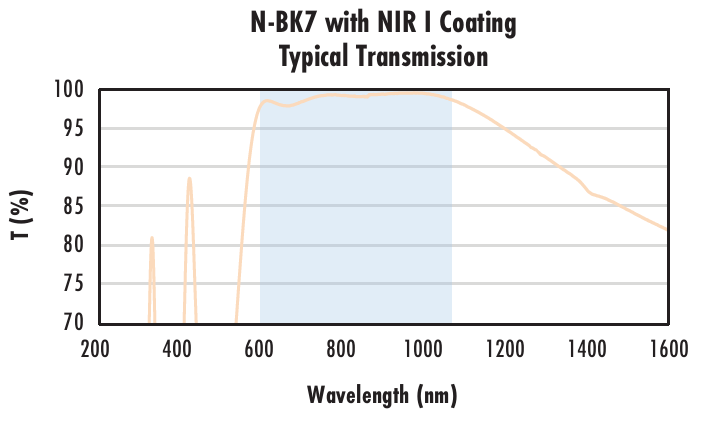

Typical transmission of a 3mm thick N-BK7 window with NIR I (600 - 1050nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Ravg ≤ 0.5% @ 600 - 1050nm Data outside this range is not guaranteed and is for reference only. |

|

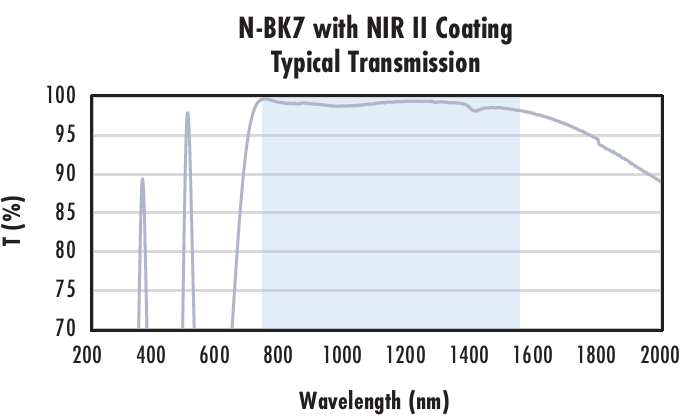

Typical transmission of a 3mm thick N-BK7 window with NIR II (750 - 1550nm) coating at 0° AOI. The blue shaded region indicates the coating design wavelengh range, with the following specification: Rabs ≤ 1.5% @ 750 - 800nm Data outside this range is not guaranteed and is for reference only. |

1-800-363-1992

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2025 | Edmund Optics, Ltd Unit 1, Opus Avenue, Nether Poppleton, York, YO26 6BL, UK

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act